Extraction

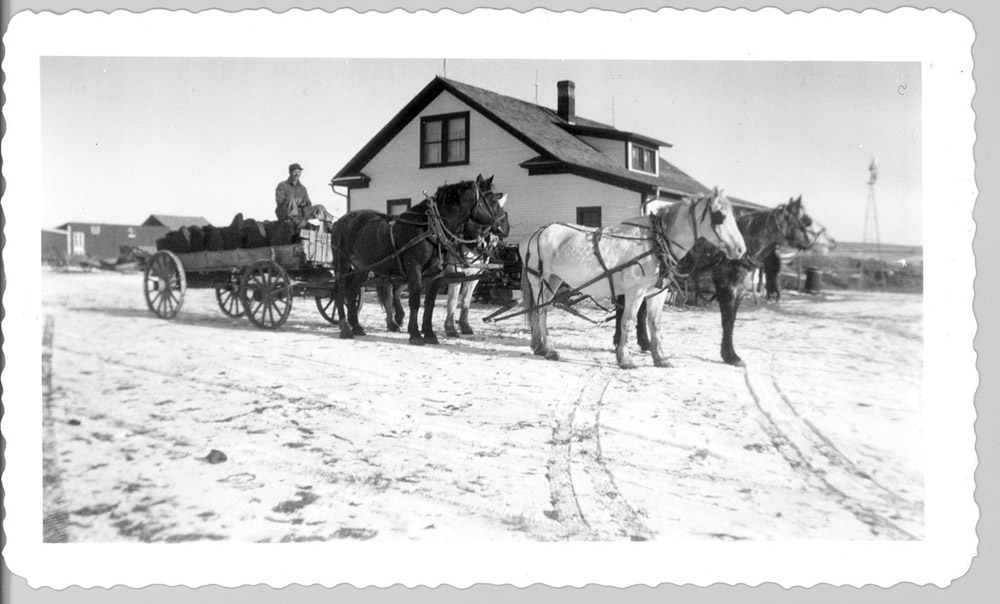

As early military and exploratory expeditions journeyed through northern Dakota Territory, the men noticed coal veins near the surface. Because the northern Great Plains lacks forests to provide wood for fuel, it was important to find a mineral substance that could provide heat for warmth and cooking. Coal was available at the surface in many places near the Missouri River. In addition, explorers saw coal seams in the rock layers of eroded hillsides. As soon as pioneers arrived, they began to extract coal from surface outcrops and shallow pits. By 1900, underground mines were operating from the Missouri Valley west to the badlands. Coal mining was North Dakota’s first major industry.

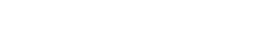

After 1920, the number of coal mines increased. There were both surface mines (also called strip mines) and underground mines. (See Image 4.) At first, strip mines were a small portion (10%) of all coal mines. By 1939, more than one-half of the state’s mines were strip mines. Strip mines produced more than one-half of the state’s total coal tonnage.

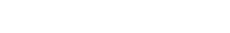

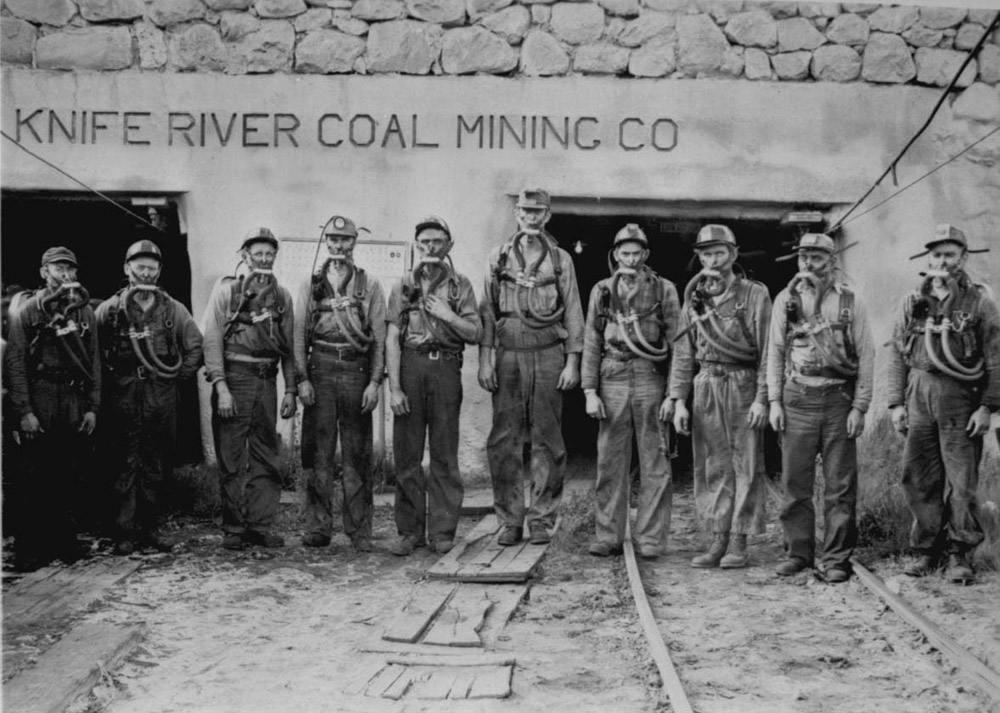

Strip mining (surface mining) involves cutting away surface layers of soil or rock and then using large machinery to remove the coal. (See Image 5.) Strip mines were more profitable than underground mines because a larger percentage of the coal was removed with less labor. Strip mines were also safer for workers than underground mines. (See Image 6.)

There were two keys to successful strip mining in North Dakota. The first was the steam shovel, a large steam-driven engine with a huge bucket that could dig into the coal vein and move the coal to a truck or storage pile. (See Image 7.) The second key was the geology of coal beds. In North Dakota, coal lay relatively near the surface in thick, level beds easily accessed by machinery.

Strip mining with draglines (to remove the overburden or surface layers) and steam shovels reduced the number of workers in the mine. In 1929, underground mines produced an average of 1,459 tons of coal per miner per year. The same year, strip mine operations produced an average 6,406 tons of coal per worker. The coal companies saw the advantage in reducing their payroll costs.

In the 1940s, natural gas and fuel oil became available for home heating fuels. The number of coal mines decreased; the remaining mines had to become more efficient in order to compete with other fuels. Coal was considered a relatively dirty fuel for private homes, so homeowners began to convert to cleaner sources of heating fuel. Coal mine operators promoted coal as a useful fuel for generating electricity that could be transmitted to large cities.

A 1948 study by the North Dakota Research Foundation suggested new possibilities for coal. Scientists experimented with using coal as a chemical that could be converted to synthetic gases, liquid fuels, fertilizers, and plastics. The new possibilities developed as coal mining declined. Both the number of mines and the total tonnage of coal decreased because fewer households and businesses depended on coal for fuel. The small coal-fired electrical generation industry was also affected by the Garrison Dam electrical power plant.

Though the coal industry was facing hard times, political leaders still believed that North Dakota had a future in energy production. In 1966, the Leland Olds Station at Stanton began to convert coal into electrical power for Basin Electric Power Cooperative. Two other power plants (Milton R. Young at Center and a second plant at Stanton) were producing electricity by 1970.

Today coal mining has a strong position in North Dakota’s economy. North Dakota has the second largest known lignite deposit in the world. (See Image 8.) Mines in this state produce 30 million tons of lignite coal each year and employ 4,000 workers.

Why is this important? North Dakota’s massive coal deposits represent energy. Scientists have learned how to harness that energy for modern uses. There may be enough coal under North Dakota to provide for a variety of energy uses for another 800 years.

The Uses of Lignite Coal

When North Dakotans began to mine coal, it was used primarily for heating homes and businesses. Eventually, railroads re-designed their engines to run on lignite coal because it was less costly than bituminous coal that had to be shipped from eastern states.

Today, however, coal has a different role in North Dakota’s economy. Lignite coal is used primarily to generate electricity. There are eight power plants in North Dakota that produce electricity from locally mined lignite. (See Image 9.) These plants supply 75 per cent of the power used in North Dakota. Power plants owned by Great River Energy send most of their power to power distribution cooperatives in Minnesota and Wisconsin.

Some of North Dakota’s power plants have applied new technologies to improve efficiency and reduce pollutants from combustion. Great River Energy has developed a technique for drying lignite and refining it (they call it DryFiningTM) which removes moisture from the coal so it can produce more energy per ton. The process also reduces sulfur and mercury (toxic pollutants) emissions.

During the 1970s, concerns about a clean environment occurred at the same time as the energy crisis. Energy demands in the United States were rising. People were encouraged to cut their energy usage, but it was necessary to find new forms of energy that were clean and safe. As a result of those concerns, a Wisconsin-based company began to develop plans for a plant in North Dakota that would turn lignite into a synthetic natural gas (synfuel) which is a cleaner fuel than coal.

This brand new concept in energy production met many problems, but each problem was resolved through legal action, congressional action, and North Dakota’s determination to see the plant built. (See Document 2.) The gasification plant began construction in 1981 and began to produce gas and anhydrous ammonia (fertilizer) in 1984. On July 28, 1984, synthetic gas made from North Dakota lignite flowed into the interstate pipeline system. (See Image 10.)

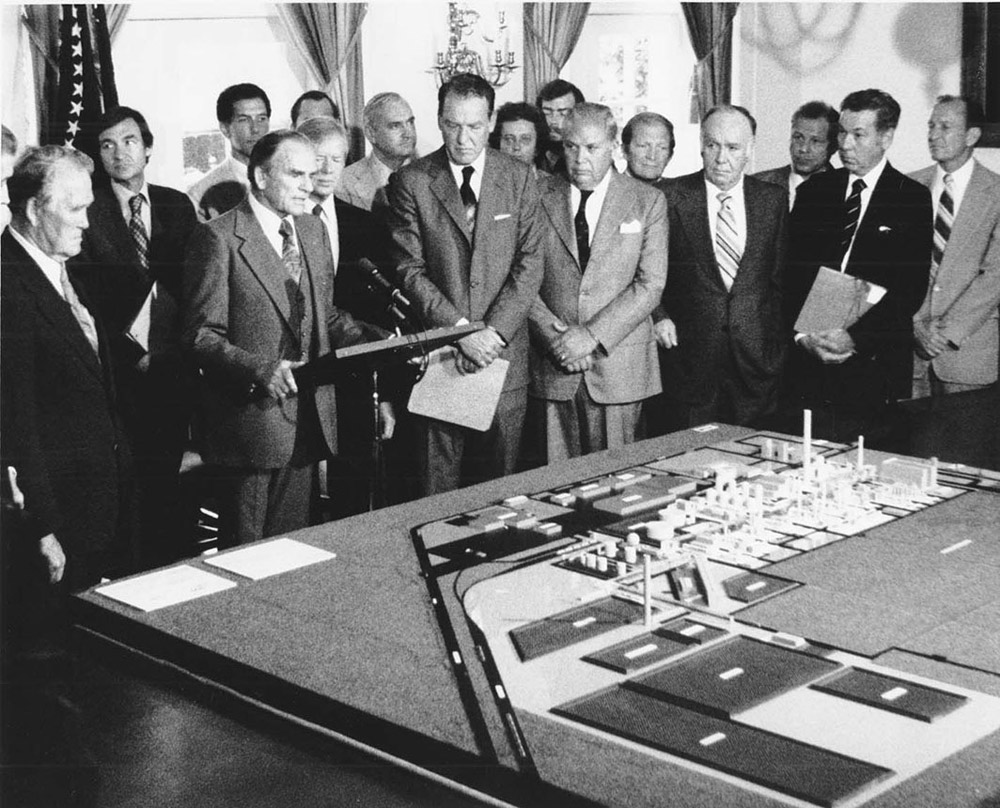

Document 2. President Carter on the Synfuels Plant

The Dakota Gasification Synfuels plant at Beulah was built with financing from a private company, support from the U. S. Department of Energy, and backing from the state of North Dakota. On July 18, 1980, President Jimmy Carter hosted a meeting that included North Dakota Senator Quentin Burdick and Governor Art Link and Mr. Seder who worked for the company building the plant. This is an edited version of the speeches. You can read the entire presentation at The American Presidency Project

THE PRESIDENT [Jimmy Carter]. This is one of those rare historic moments in the history of a nation and its interrelationship between government and the private sector of our economy to launch a new vista for improvements and for a better quality of life for all Americans. . . . This project here, which is a very rapid-moving project, since we only signed the Energy Security Act . . . less than 3 weeks ago, is another example of the progress that is being made toward making our Nation energy secure. I would like to announce this morning and deliver to these assembled leaders the approval by the Federal Government of a $250 million loan guarantee for the construction of this coal-to-natural gas conversion plant to be built in North Dakota. I would particularly like to thank Governor Art Link and Senator Quentin Burdick for the leadership role they have played in coordinating the Government effort. . . . This plant will be the first commercial coal-to-gas plant ever built in our Nation. . . .We expect it to produce the equivalent of 9 million barrels of oil per year, and this will mean, during the construction phase, the hiring of about 3,000 workers and the permanent hiring of about 500 [people] to operate the plant, highly advanced in its design. . . . It's with a great deal of pleasure that I deliver to Mr. Seder this conditional commitment to guarantee the $250 million in loans from which a great deal more money can be derived from private sources for the construction of this remarkable plant. We'll be observing its progress with great interest and anticipation, and the entire Nation will be benefited by this project. . . .

THE PRESIDENT. Art [Governor Link], would you like to comment?

GOVERNOR LINK. I want, first of all, President Carter, to thank you and the Department of Energy for this support for the construction of the first coal gasification plant in the Nation. . . . There's a significance connected with this that we should also note, that it's being built on the same ground and in conjunction with an electric coal-fired generating facility operated by Basin Electric. And they have a close working relationship that will put into effect a great many economical, innovative procedures, both from the economic and utilization of the fuel and also from the environmental impact effects of this kind of development. And so, Mr. President, all of us in North Dakota and those who have worked very closely, particularly in promoting this plant, are deeply grateful to you, the Department of Energy, and to your foresight and support and encouragement in the progress that we've made in getting this project off the ground as we are this morning. . . .

However, in 1985, some of the partners that had financed the plant said they would abandon the plant and stop paying on loans. The U. S. Department of Energy took over ownership of the plant. Basin Electric Cooperative took an interest in the plant. Several other companies were interested in purchasing the synfuels plant, but Basin Electric submitted the winning bid in August 1988. Basin Electric formed a subsidiary (an affiliated company) called Dakota Gas to operate the plant. Dakota Gasification Synfuels Plant at Beulah is one of two in the world; another, much larger plant is located in South Africa.

Dakota Gasification also produces fertilizer (anhydrous ammonia), ammonium sulfate, crude cresylic acid, phenol, naphtha, krypton-xenon, liquid nitrogen, diesel exhaust fluid, tar oil, urea, and a very pure form of carbon dioxide (CO2). The CO2 is piped to Canada where it is used in oil production. The production of synthetic natural gas uses about 13 per cent of North Dakota’s annual coal production.

An important by-product of coal-fired power plants is fly ash.The new addition to the State Museum at the Heritage Center in Bismarck uses fly ash in some of the concrete support structures. Support columns are made of about 50 per cent fly ash. Lesser amounts of fly ash were used in other parts of the building’s concrete structure. Fly ash combined with cement makes a very strong substance for supporting a building. This is the material that remains after coal has been burned. Once the fly ash is removed from the plant, it can be used to replace some of the cement in concrete or roads.

Why is this important? North Dakota’s first major industry was coal mining. Coal mining and coal plants continue to be important to the state’s economy. Though lignite coal presents several problems as a fuel, innovative techniques changed the way coal is used. Coal-fired power plants produce electricity and provide many jobs for North Dakota residents. Innovations resulted in cleaner coal plants and products such as fertilizers, synthetic natural gas, CO2, and fly ash. Because coal is essentially a dirty resource, we have looked for new ways to make it safe, efficient, and useful.

Coal Land Reclamation

In 1970, the U.S. Congress passed the Clean Air Act. Two years later, Congress passed the Clean Water Act. These two measures responded to Americans' concerns about the quality of the environment in which they lived and how it affected their health.

North Dakotans were interested in environmental quality, but the foundation of their concern was the protection of agricultural lands. On the one hand, surface mining and coal-fired power plants provided jobs and energy security. On the other hand, North Dakota had a long-standing tradition of farming and ranching. The two views were often at odds. The middle ground between these two views was found in reclamation of mined areas.

Reclamation means making the worked-over strip mine areas useful again. In the 1930s, the Game and Fish Department began experimenting with the idea of making strip mine spoil piles into good habitat for wild game. Spoil piles were the piles of dirt and rock taken from the surface to expose a coal vein. Spoil piles accumulated near a former mining operation. (See Image 11.) The Game and Fish department planted sweet clover, trees, and grasses on the piles. Sweet clover grew well and held the soil in place against wind and water erosion until native grasses and shrubs could mature. The plan was popular, and other groups, including Boy Scouts, contributed to reclamation of spoil piles.

In the 1960s, the Knife River Coal Company leveled its coal spoils and planted trees, grass, and shrubs. However, there was still some uncertainty about the best way to reclaim the spoils. Leveling was a good idea if the land was to be used for hay land or grazing. But for wild animal habitat, leveling was not necessary.

In 1967, the North Dakota legislature decided to study the problem. As a result, the 1969 legislature passed a surface mining reclamation bill that “encouraged” mine operators to restore the land after the mine operation was finished. (See Image 12.) This law was amended in 1975 to outline specific requirements for reclamation. The law requires mine operators to put the land back as they found it. This means that before receiving a permit to operate a surface mine, the mine operator has to carefully survey the topography and soil of the area and save five feet of topsoil and subsoil as it is removed from the coal vein. When the mining has finished extracting the coal, the operator has to re-place the soil, make the land have the same contours as it had before the mine was opened, and plant grasses, trees, shrubs or whatever was appropriate to the landscape. The operator has three years to complete the reclamation and has to pay for the work. In addition, the mine operator has to be sure that the surface land owners’ water supply was not damaged in any way.

Two years after North Dakota passed the strong coal lands reclamation law, the federal government passed a very strict reclamation law. In 1979, North Dakota modified its 1975 law to meet the standards of the federal law. However, in some ways, North Dakota’s 1975 law was stricter and better suited to the type of mining that was being done in North Dakota.

Both the federal and state laws brought some changes. Small mines began to close because of the high costs of reclamation. Some of the larger mines began to buy surface rights to the mining land. Although the mine company owned the land, it still had to meet reclamation requirements, but many mines found the process more efficient and less costly.

Throughout the 20th century, Americans were using more and more energy in all forms. Nuclear power plants were built in many states to help meet the rising need for electricity. North Dakota’s coal reserves appeared to hold part of the solution to the energy crisis. But many North Dakotans did not want to see the landscape destroyed in order to feed America’s energy consumption.

Governor Arthur Link was a leader in coal lands reclamation. (See Image 13.) He was a rancher from Alexander and knew the importance of agriculture to North Dakota’s economy. In 1973, he spoke to a meeting of the Rural Electric Cooperatives where he said:

Let us not permit the opportunity of quick economic gain to overshadow our concern for the long-range benefit and prosperity of succeeding generations. We do not want to halt progress . . . we simply want to insure the most efficient and environmentally sound method of utilizing our precious coal and water resources for the benefit of the [most] people possible.Governor Link finished that speech by saying:

“And when we are through with that, and the landscape is quiet again, when the draglines, the blasting rigs, the power shovels and the huge gondolas cease to rip and roar;

And when the last bulldozer has pushed the last spoil pile into place and the last patch of barren earth has been seeded to grass or grain;

Let those who follow and repopulate the land be able to say,

“Our grandparents did their job well. This land is as good as, and, in some cases, better than, before.”

Only if they can say this will we be worthy of the rich heritage of our land and its resources.”

Today, reclamation is a routine process for surface coal mining companies. After the three-year reclamation process, the companies continue to be responsible for the productivity of that land for 10 years. Since the law was written, more than 26,000 acres of mine land have been reclaimed. Mine companies continually work on reclamation every year at an average cost of about $30,000 per acre.

Why is this important? North Dakota’s coal resources are important to the residents of this state who get most of their electricity from coal and to millions of other people in nearby and distant states. Coal-fired power plants send electricity over the nation’s electrical system to distant locations. While electricity is very important to every aspect of our lives, the land is also important. The land provides us with clean air and clean water, places for birds and animals to live, and a place to grow our food. The North Dakota reclamation law benefits both mining and agriculture.